1

2

3

4

5

6

Scepter™ Fiber Optic Polisher

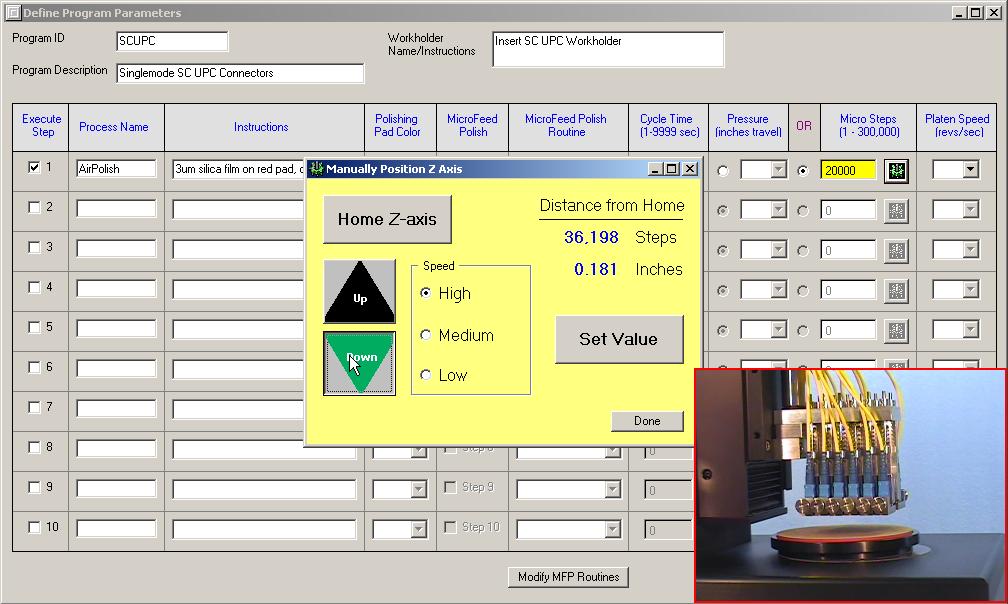

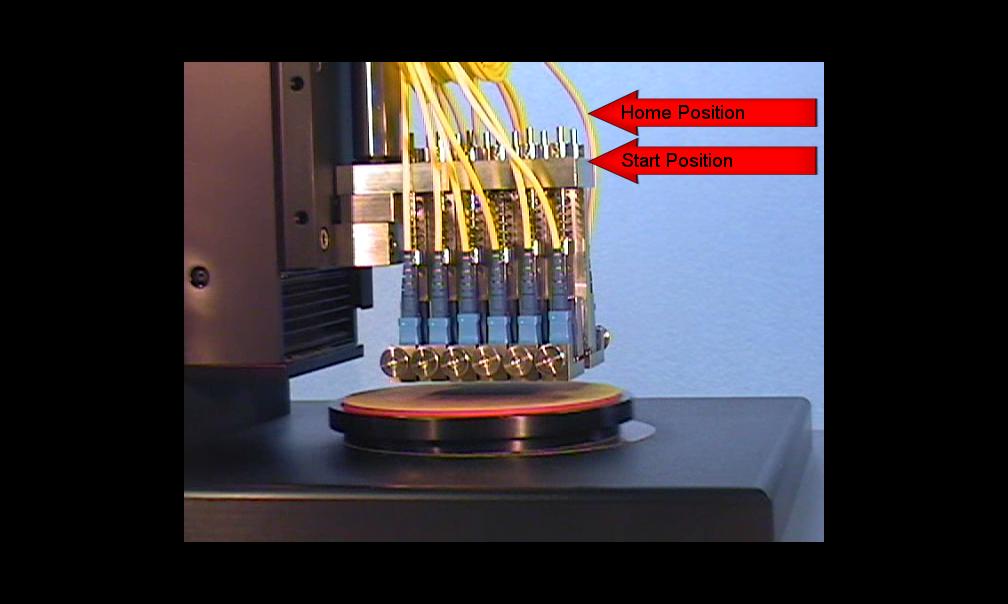

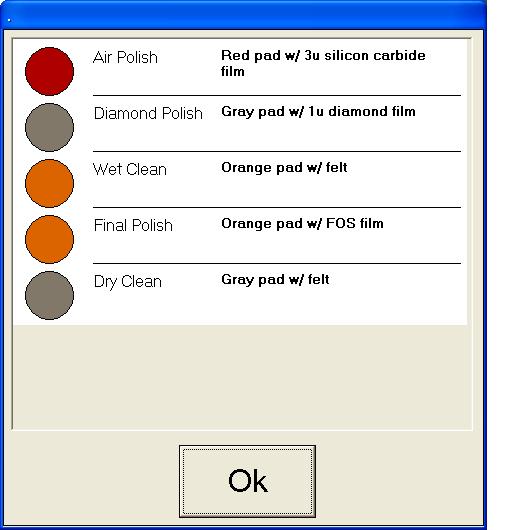

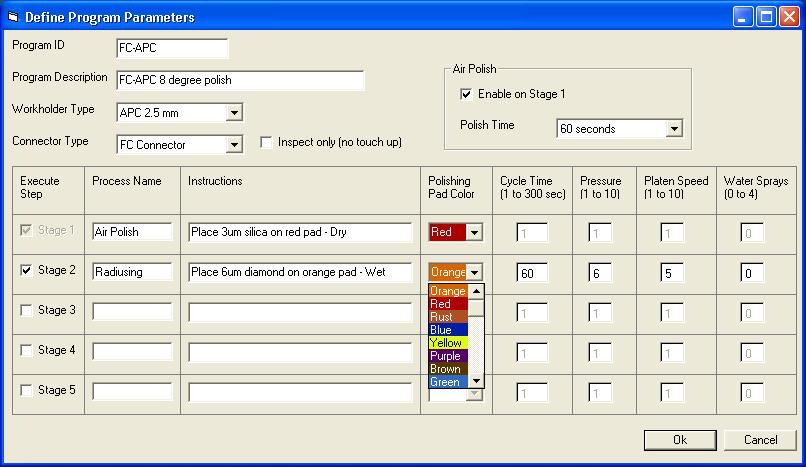

Scepter™ is PC controlled for consistent and Telcordia compliant mass polishing of optical connectors and bare fiber. Technicians are prompted through each process step via the user friendly interface. Various polishing procedures are easily programmed for all connector types and surface finishes. Scepter™ polishing fixtures incorporate Krell’s unique independent suspension and optical alignment design for uniform polishing at each connector position, and maximum consumable film usage. In-line video inspection streamlines production and minimizes component handling.

Starting at

$ 27,000

Related Q&A:

April 29, 2020, 3:12 p.m.

Q

How does Scepter accommodate long cable assemblies?

A

Cable management brackets for supporting cable assemblies, connector patchcords and fibers are provided with each Scepter.

April 6, 2020, 8:28 p.m.

Q

Are there any inspection options with Scepter?

A

Yes, the SpecVision videoscope engages with Scepter workholders for connector surface inspection.

April 2, 2020, 4:12 p.m.

Q

Can the Scepter polish bare fibers?

A

Yes. Please forward dimensions to sales@krelltech.com.

March 31, 2020, 8:24 p.m.

Q

How many connectors can Scepter polish at once?

A

12

March 31, 2020, 8:24 p.m.

Q

What size film does Scepter use?

A

5"

March 26, 2020, 5:12 p.m.

Q

How many connectors can I polish simultaneously?

A

You can polish up to 12 connectors simultaneously.

Feb. 7, 2020, 5:17 p.m.

Q

What size is the Scepter platen?

A

Scepter platen supports 5" (5 inch) diameter polishing films.

Jan. 3, 2020, 4:23 p.m.

Q

How many SC/UPC connectors can Scepter polish simultaneously?

A

Scepter can polish 12 connectors. Scepter X2 can polish 24 connectors.