PRODUCTS

NOVA™ Surface Inspection Module

NOVA™'s Surface Videoscope allows the in-line inspection of polished surfaces while the component is still loaded in the polisher. This minimizes material handling and streamlines photonic production compared to the traditional process of transfering components to off-line inspection stations. Polishing and specification compliance can be determined in a single workcell.

DART Bare Fiber Adapter

DART™ opens new worlds for traditional bare fiber holding. In addition to temporarily securing a fiber at a fixed position, an integrated roller mechanism moves the fiber in and out of the adapter. This allows for variable protrusion and retraction of the fiber endface relative to DART™’s precision support ferrule.

The universal 2.5mm ferrule interfaces with a variety of equipment and components such as polishers, electro-optic packages, test equipment and more. DART™ can be configured for fiber diameters ranging from 80um to >1mm using interchangeable ferrule tips.

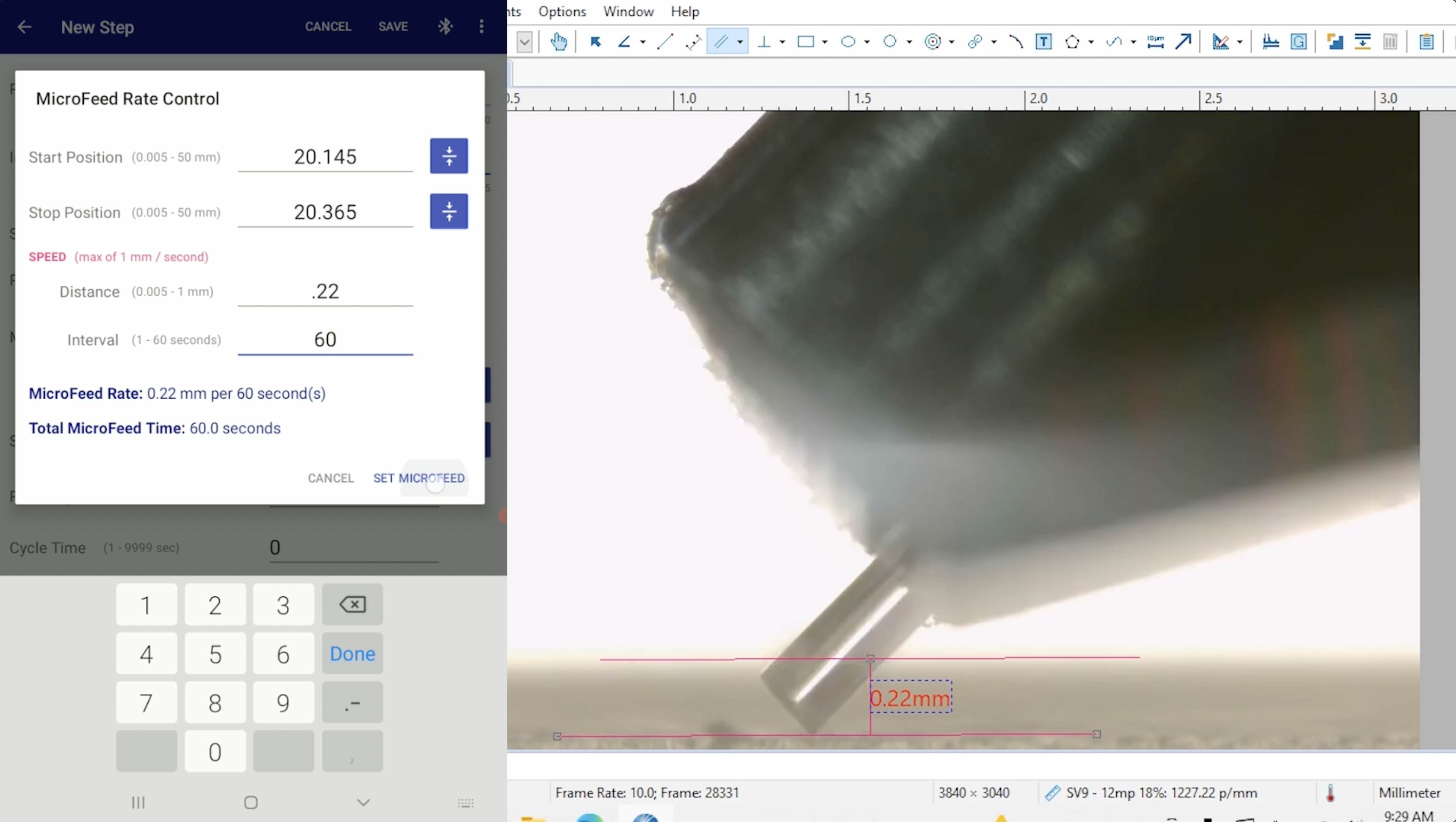

NOVA™ Operation Software Upgrade Kit

This new software kit upgrades NOVA™ polishers with the Enhanced Microfeed Feature. This polishing routine provides greater programming flexibility for advancing components to the polishing surface at slower and more controllable rates. Version 1 NOVA software was limited to 10 pre-programmed Microfeed rates, with the slowest being 100um per second. Version 2 software allows a user to customize rates as slow as 5um per minute. This yields precise removal of material stock and continual component advancement. The Enhanced Microfeed is ideal for larger optical surfaces, delicate bare fibers, and connector air polishing.

V2 provides the ability to create "pop-up" window prompts in between each polishing step. This is very useful as reminder to technicians to clean fibers, inspect polish lengths, confirm geometry, etc. before initiating the next process step.

New folder management allows programs to be organized according to connector types, fiber diameters, component, etc.

The Photonic CleanTouch™ Stick | Solvent-Free Optical Cleaning for Fibers, Connectors, and PICs

The Photonic CleanTouch™ Stick from Krell Technologies is a compact, cost-effective, one-touch cleaning solution for critical photonic components. Engineered with a proprietary photonic-grade substrate, it’s ideal for precision cleaning across a wide range of optical surfaces, including:

-

Optical fibers and ferrules

-

Fiber optic connectors

-

Photonic integrated circuits (PICs)

-

Planar waveguides

-

Cleanroom components

This single-step cleaning method removes all contaminants—such as dirt, dust, and residual buffer coatings—without leaving behind residue. The component is simply touched against the cleaning portion of the stick, causing debris to transfer and stay on the substrate. No solvents, compressed air, or costly dispensers are required.

Key Features:

-

Solvent-free, chemical-free cleaning

-

One-touch operation for fast in-process or post-process use

-

Compact, portable, and easy to store

-

Effective for both lab and field applications

-

Sold in packs of 25

Whether used in fiber optic manufacturing, PIC packaging, or photonics R&D labs, the CleanTouch™ Stick offers safe and efficient cleaning without the need for additional tools or consumables.

Gator™ Photonic Component Cleaner

The Gator™ from Krell Technologies is a compact, ergonomic cleaning tool designed to safely and effectively remove dirt, dust, and debris from photonic components—including fiber optic connectors, ferrules, bare fibers, photonic integrated circuits (PICs), and waveguides.

Engineered for versatility, Gator™ supports both dry and wet cleaning methods. Its reusable substrate allows for dozens of cleaning cycles before disposal, making it ideal for field technicians, production environments, and cleanroom applications.

Whether preparing fibers for fusion splicing, connector termination, bare fiber polishing, or final inspection, Gator™ provides reliable cleaning for in-process and post-process workflows.

Key Features:

-

Safe for delicate photonic surfaces

-

Compatible with dry and solvent-based cleaning

-

Compact, portable, and reusable design

-

Supports lab use, field service, and high-volume production

-

Removes buffer coating residue, particles, and debris

-

Sold in packs of 50

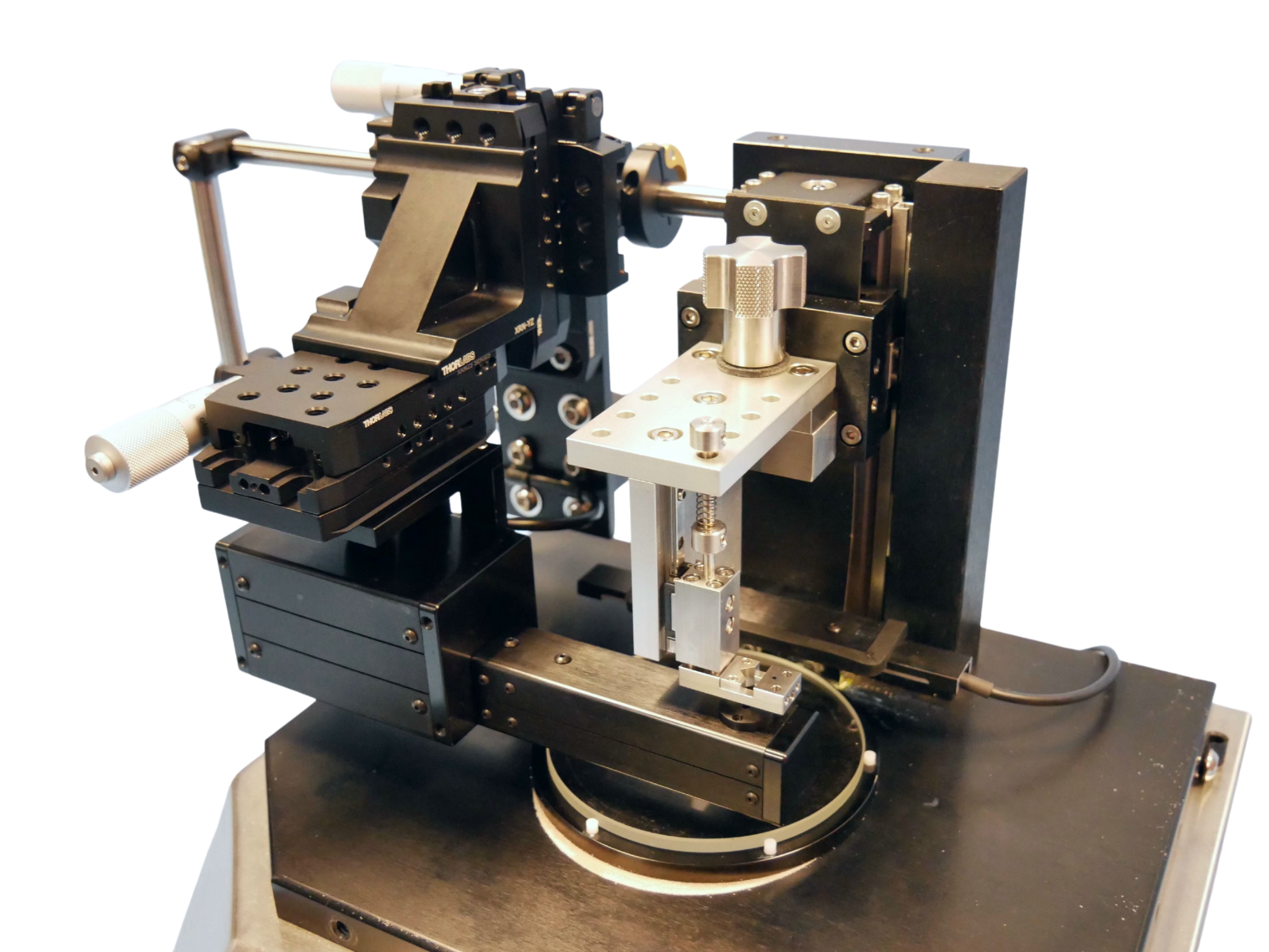

InSight™ In-line Video Inspection Station

InSight™ In-line Video Inspection Station is a dedicated video station for the inspection of fiber optic connectors and photonic components. All Krell polishing workholder fixtures can quickly engage with this system allowing in-line inspection without the need to remove the connector/termini/chip/component from the polishing fixture. This streamlines quality assurance and minimizes the change of component damage and contamination that can occur when removing and transfer parts back-and-forth between polisher and microscope. Magnification levels can easily be change by the simple exchange of optical objectives. InSight™ supports NOVA™, Scepter™, SpecPro™, FLex™, Radian™ and Proton polishing equipment and machines.

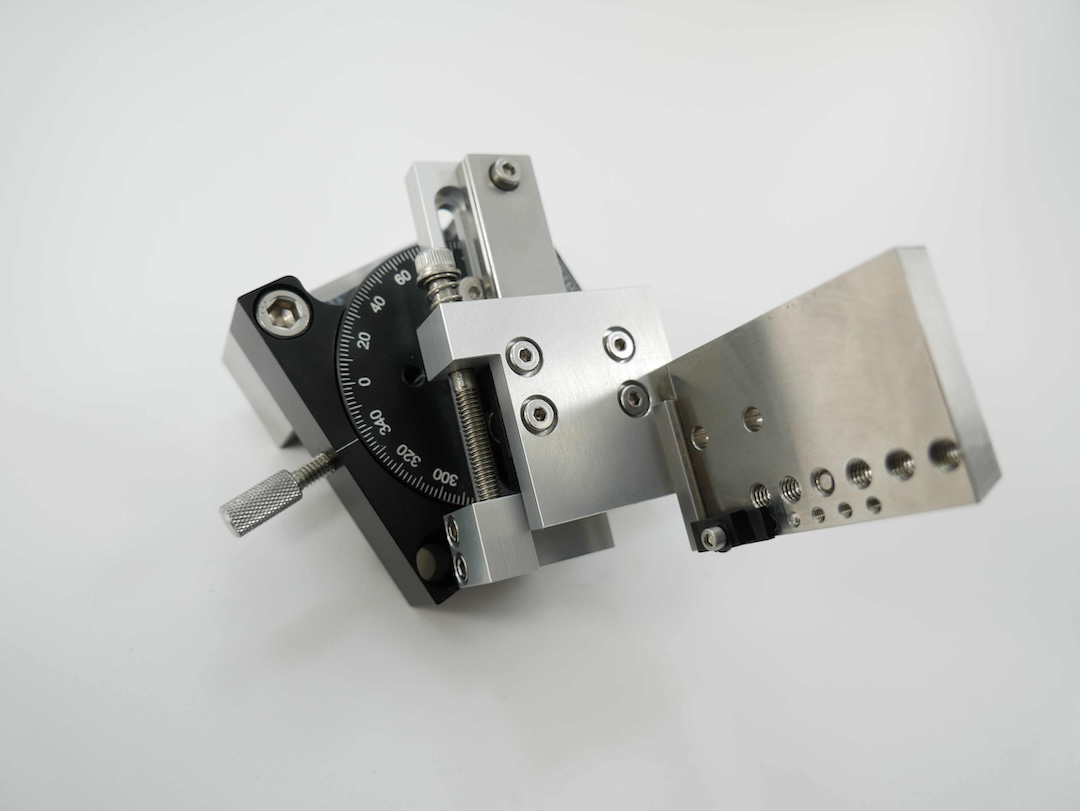

NOVA™ Workholder for PICs/Waveguides, Fiber Arrays, and Optical Chips

The NOVA™ Workholder is designed for precise polishing and shaping of photonic components, including waveguides, fiber arrays, and optical chips. It ensures high-quality finishes and repeatable results, making it an essential tool for photonic component production.

Key Features:

Adjustable Polishing Angles: 0° to 45° for flexible processing.

Component Size Compatibility:

- Standard: 3mm to 25mm edge width

- Extended Length Model: Up to 50mm

- Supports thicknesses from ~0.5mm to <5mm

Workholder Options:

- Single-Position Variable Angle (manual or automated)

- Four-Position Variable Angle (manual)

- Eight-Position Fixed Angle

PIC & Waveguide Carriers:

- Ergonomic and repeatable mounting

- Seamless integration with NV-FLEX and NV-FLEX-A fixtures for optimal polishing

The NOVA™ Workholder provides the precision and flexibility needed for photonic manufacturing, ensuring consistent edge preparation and polishing for PICs, optical chips, and fiber arrays.

SkyBrite™ Photonic Cleaning Wipes

Soft. Strong. Smart. And Blue.

SkyBrite™ is your go-to lint-free wipe for cleaning optical and photonic components — including your Krell machine itself. Made from a durable hydro-entangled polyester and cellulose blend, these wipes deliver exceptional performance dry or with solvents. Their signature blue color darkens when wet, giving you instant visual feedback and precise control during cleaning or film prep.

Key Benefits

✔️ Lint-Free – Cleanroom rated and leaves no particles behind

✔️ Darkens When Wet – Visual control of solvent coverage

✔️ Scratch-Free – Ultra-soft for delicate optical surfaces

✔️ Solvent-Resistant – Stays strong with MEK, acetone, IPA

✔️ Reusable – Durable for multiple cleanings

Applications

-

Cleaning KrellTech machines and workholders

-

Smoothing polishing films after application

-

Optical connector and ferrule care

-

Photonic integrated circuit surface prep

-

Lens and microscope cleaning

-

General cleanroom wiping for photonic devices

Product Details

-

Size: 4" × 4" (10.16 cm × 10.16 cm)

-

Material: Hydro-entangled polyester & cellulose

-

Cleanroom Rating: Class 100 compatible

-

Packaging: 250 wipes per case

Why SkyBrite™?

With over 30 years of expertise in photonic component processing, KrellTech selected SkyBrite™ for its unmatched accuracy, reliability, and versatility. Whether cleaning optics, prepping surfaces, or maintaining equipment, SkyBrite™ ensures a clean, consistent result — every time.