PRODUCTS

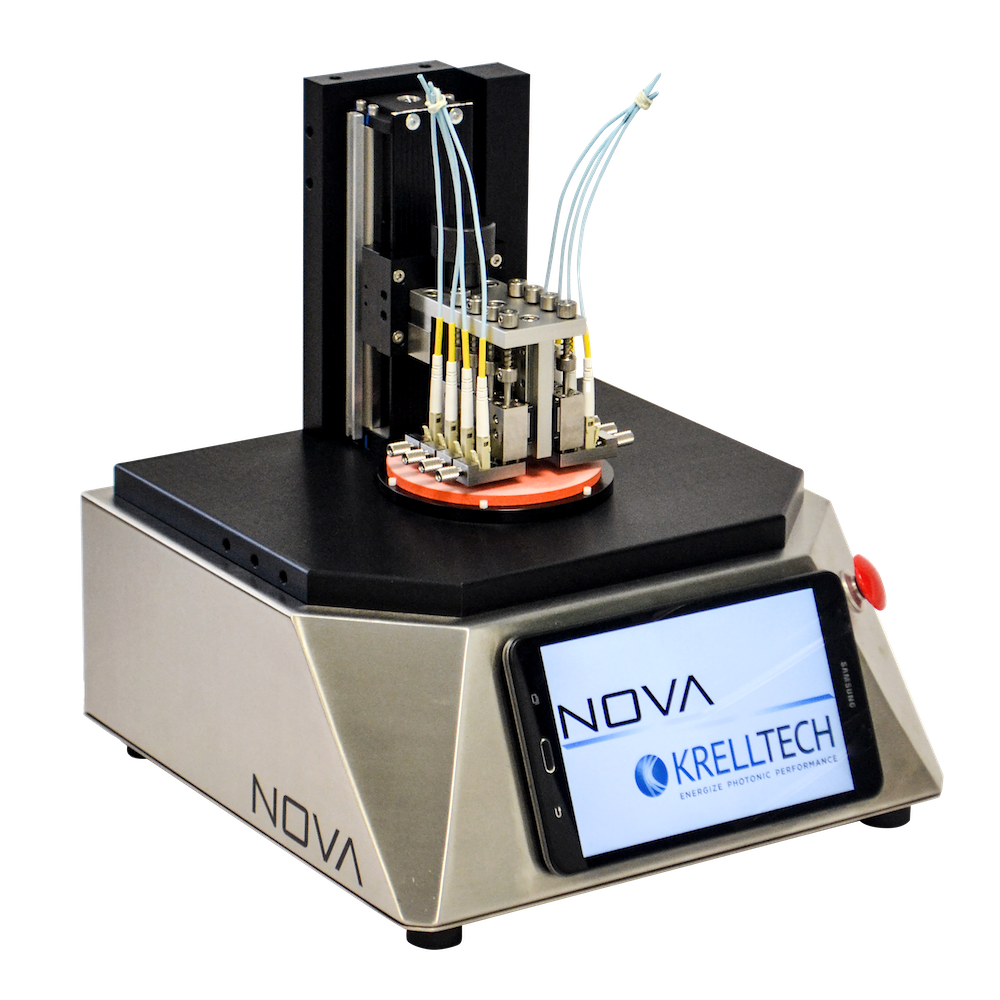

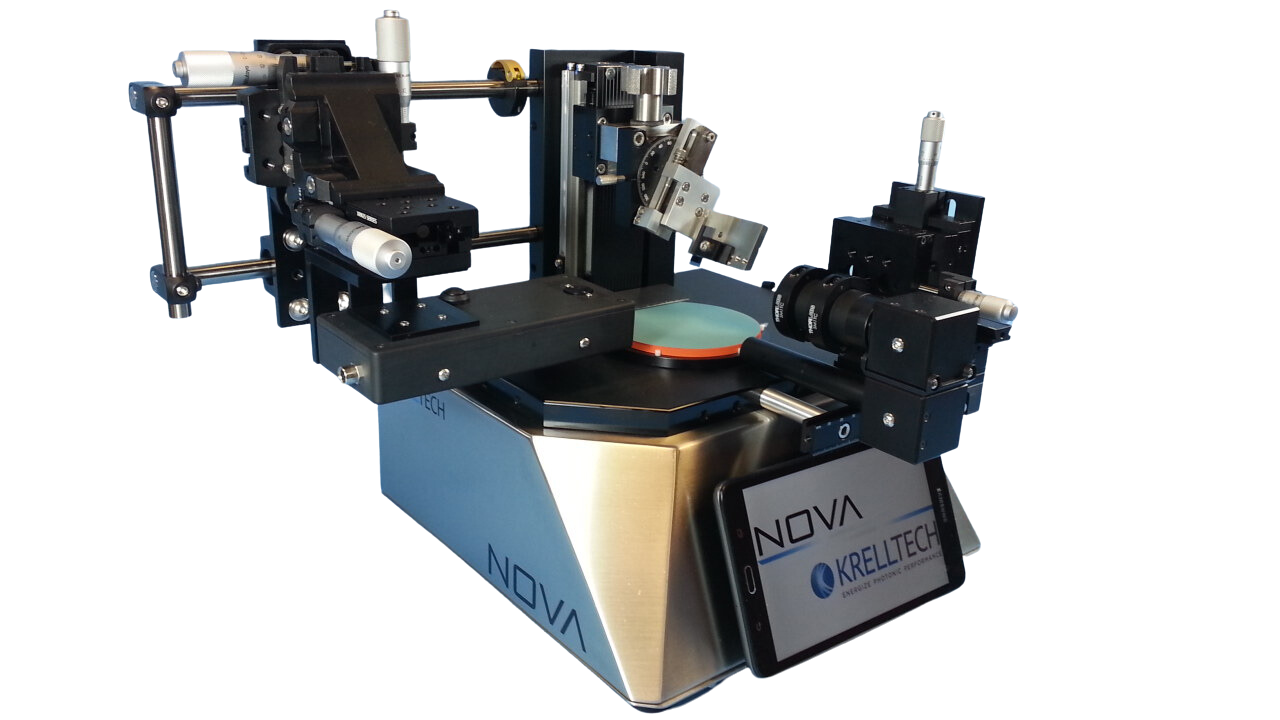

NOVA Optical Polishing System

Maximum flexibility for optical surface processing is now available with NOVA™. KrellTech has integrated the proven performance and features of its industry leading Scepter, Trig and FLex polishers into this configurable and cost-effective system.

NOVA™ supports a variety of polishing applications from connectors to PICs/waveguides, and bare fibers to custom components. NOVA™ is scalable from R&D projects to high volume production and features wireless tablet operation with a familiar and intuitive Android interface.

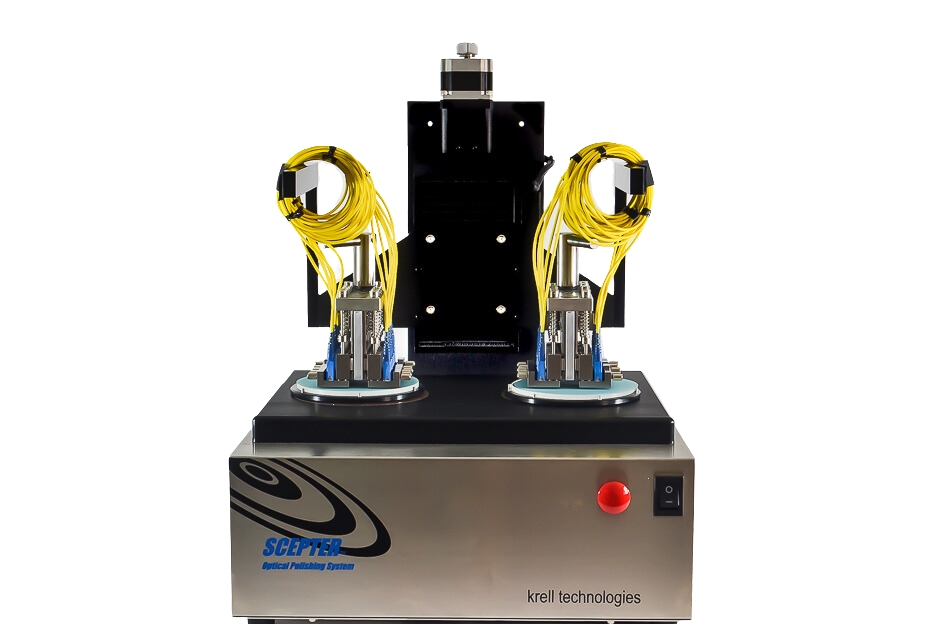

Scepter™ Fiber Optic Polisher

Scepter™ is PC controlled for consistent and Telcordia compliant mass polishing of optical connectors and bare fiber. Technicians are prompted through each process step via the user friendly interface. Various polishing procedures are easily programmed for all connector types and surface finishes. Scepter™ polishing fixtures incorporate Krell’s unique independent suspension and optical alignment design for uniform polishing at each connector position, and maximum consumable film usage. In-line video inspection streamlines production and minimizes component handling.

Scepter X2 Dual Position Connector Polisher

Connector polishing capacity has been doubled with the Scepter X2 System. X2 has the same footprint as KrellTech's original Scepter connector polisher, but now supports two polishing fixtures. Up to 24 connectors, Mil-spec termini and ferrules can be processed simultaneously using KrellTech's patented Independent Suspension workholders. If two High-Capacity Workholders are used, 58 components can be processed during the same polishing session. As with all KrellTech polishers, optical performance and surface geometry exceed all industry standards including Telcordia and IEC.

Proton™ Field and FTTX Polisher

Proton™ consistently achieves Telcordia compliant, singlemode UPC and APC finishes in a handheld and battery operated package. Proton™ incorporates the same Independent Suspension (IS) and optically aligned workholder design found in Krell’s Scepter™ Mass Production Polishing Systems. Proton™ can polish connectors sideways and at most orientations, permitting access to cabling in the tight confines of datacom wire closets, LAN cross-connects, and CATV fiber nodes. Proton™’s portability lends itself to various military and aerospace applications and networks in which field-deployed optical connectors are terminated or require servicing and repair. Mil-spec components and termini including M29504, LuxCis, ARINC 801, ELIO, MC5, RSC, etc.

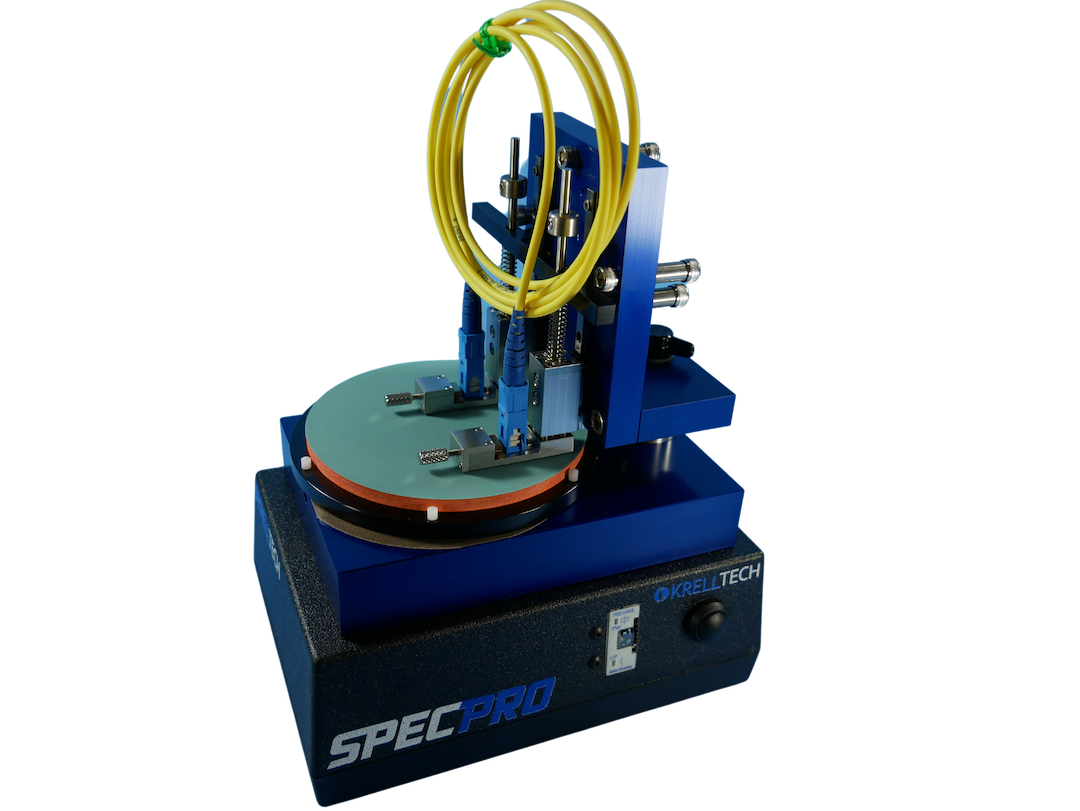

SpecPro™ Connector Polisher

SpecPro™ is designed to yield singlemode performance for R&D and medical applications, low volume cable assembly production, and field environments. Up to four components can be simultaneously polished, including industry standard connectors, multifiber ferrules, MIL-spec termini, optical bundles, endoscopes and bare fibers. SpecPro is also ideal for repairing and retro-polishing damaged connectors. SpecPro™ incorporates Krell’s unique independent suspension feature for more uniform and consistent polishing at each connector position. Krell’s SpecVision™ Video Inspection System can also interface with SpecPro™ for in-line viewing of fiber finishes. In addition to its compact and portable packaging, SpecPro™ features both AC and battery operation.

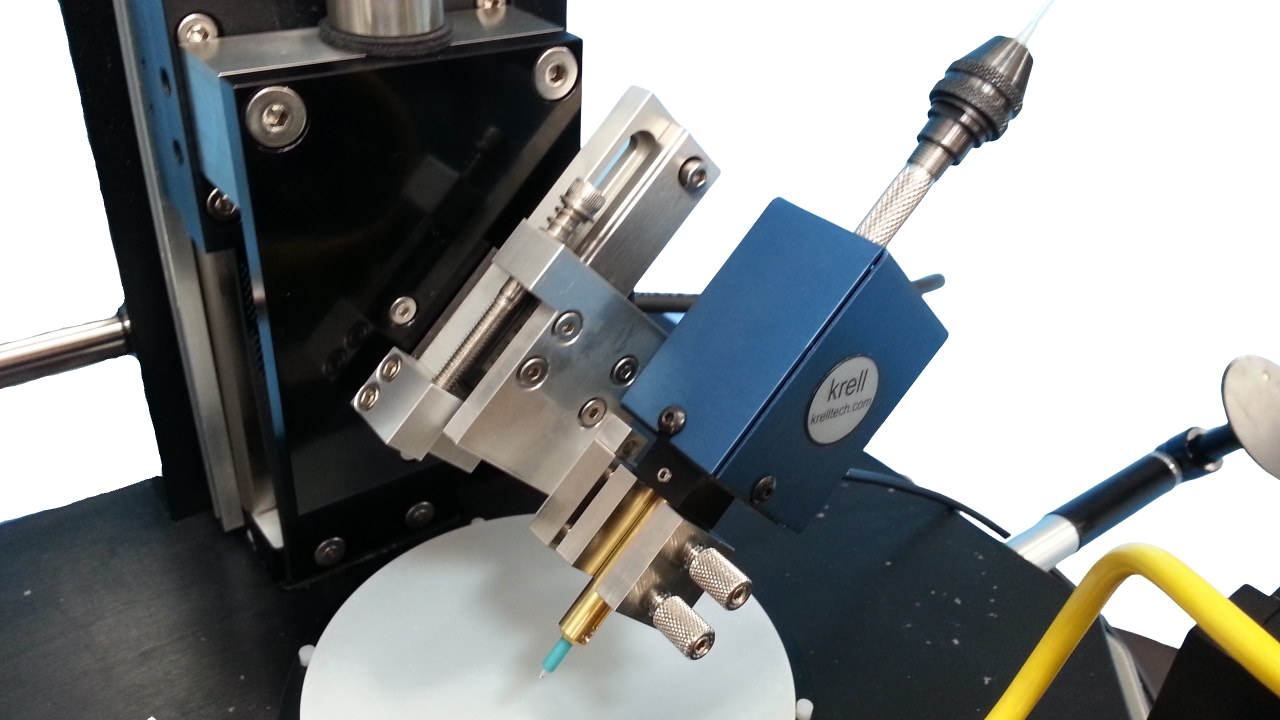

NOVA GEO™ PIC Waveguide & Array Polishing System

NOVA GEO™'s flexible processing platform allows it to be configured for polishing waveguides, PIC optical chips, PLCs and fiber arrays. Polished endface angles can be varied from 0 to 50 degrees using either manual or automated workholder stages. GEO™'s component mounting plate is adjustable for varying edge widths and thickness.

Optional video inspection systems monitor the polishing process and inspect the polished surface directly in GEO™. In-line viewing minimizes material handling and is a means to confirm endface geometry before removing the component from the machine.

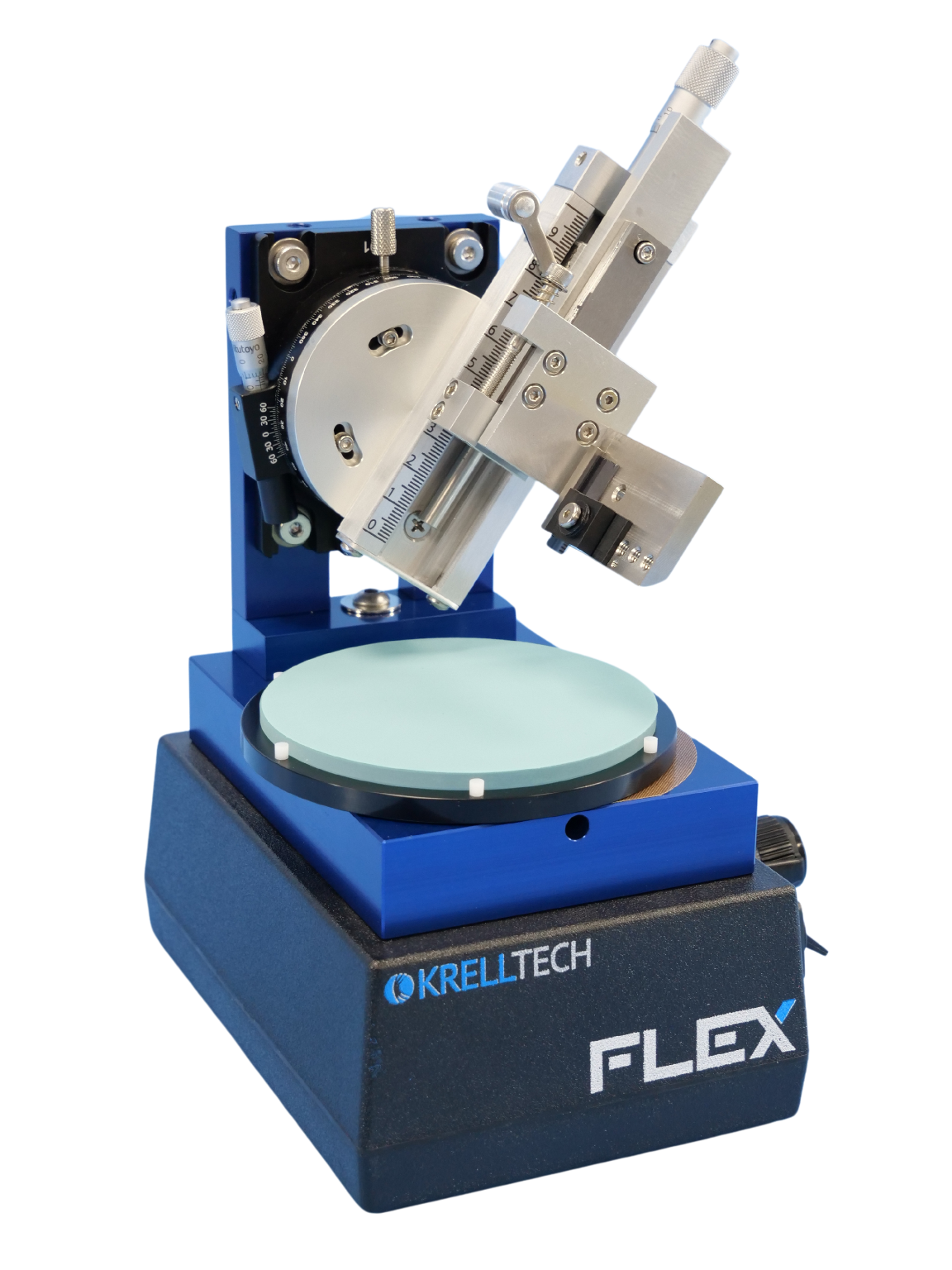

FLex PIC & Waveguide Polisher

FLex is capable of polishing a variety of waveguide components such as PLCs, PIC optical chips and fiber arrays. It integrates universal carriers that can accommodate components of various dimensions, as well as the ability to polish at variable angles.

NOVA™ Bare Fiber Polishing System

NOVA™'s flexible processing platform allows it to be configured for polishing bare fibers. Fibers can be polished at variable angles from 0 to 50 degrees using specialized workholders and adapters. A variety of fiber types from standard singlemode to PM, and sapphire to PCF can be processed. A quick swap-out of adapters allow the polishing of fiber diameters from 80um to >3mm.

Optional video inspection systems monitor the polishing process and inspect the polished surface directly in NOVA™. In-line viewing minimizes material handling and is a means to confirm endface geometry before removing the fiber from the machine.

Conical and chisel fiber tips can also be formed using the Orbit™ Shaping Module (see below).

Radian™ Bare Fiber Polisher

Krell’s Radian™ System provides the ability to polish optical fibers at user-selectable and variable angles. Interchangeable adapters accommodate fibers of various diameters and material types. Bare fiber, glass rod or optical bundle polishing is possible with high speed processing. The rotary stage can be interchanged with a variety workholders for polishing fiber optic connectors. Radian™ is ideal for laboratory, R&D and low volume manufacturing applications.

Expand Radian’s™ versatility beyond

bare fiber processing. Adapters are

available for polishing a variety of industry standard and custom

connector/ferrule types, as well as rods/lenses. Polish components to flat, UPC and angled geometries.

Orbit™ Bare Fiber Coning and Chisel System

Orbit™ enhances NOVA™'s bare fiber processing with conical and chisel tip shaping. Unique fiber tip geometries can be formed for lensing, sensing and light guiding applications.

The fiber rotation module can be mounted on standard NOVA™ variable angle and waveguide workholders. Fiber "spin" speed is user adjustable, and can be set for continual rotation or the unique "360 auto-reverse" motion that prevent fiber twisting and torquing.

All variables are entered and selected via a touchscreen on the Orbit™ controller. When combined with NOVA™ Auto-Angle Workholders, Orbit™ precisely positions the polishing fixture at the designed angle on a repeatable basis.